At Hindusthan Fabrication Industries, we aim to deliver innovative, durable, and scalable engineering solutions. From fabrication to transformer tank manufacturing, we turn ideas into reliable industrial products.

By combining experience, technology, and precision, we help industries grow with confidence. Our focus is on quality, performance, and long-term client satisfaction.

Hindusthan Fabrication Industries was established to deliver reliable fabrication and transformer tank solutions. With experience and expertise, we've earned a trusted name in industrial manufacturing.

Our mission is to provide durable, precise engineering that fuels industrial growth. We value quality, safety, timely delivery, and continuous innovation in every project we undertake.

At Hindusthan Fabrication Industries, we provide comprehensive engineering solutions through four key services—Custom Steel Fabrication, Transformer Tank Manufacturing, CNC Plasma Cutting, and Precision Transformer Core Channel Production. Our integrated approach combines advanced technology, skilled workmanship, and strict quality control to deliver products that are durable, efficient, and performance-driven. Whether it’s building robust industrial structures, crafting high-capacity transformer tanks, executing intricate metal cuts, or ensuring transformer core stability, we are committed to delivering excellence across every stage of the manufacturing process.

Our fabrication services are designed to meet the structural and industrial needs of diverse sectors. We offer precision-engineered solutions in structural steel fabrication, sheet metal works, welding, and customized assemblies. Whether it’s heavy-duty infrastructure or high-volume production, our facilities and experienced team ensure top-tier quality with every component.

We utilize the latest technology and advanced machinery to maintain strict tolerances and deliver products that meet exact specifications. Our commitment to quality control, combined with robust project management, guarantees timely delivery and consistent performance. From initial design consultation to final inspection, we work closely with clients to tailor solutions that maximize efficiency, durability, and cost-effectiveness.

We manufacture high-quality transformer tanks tailored to the exact specifications of our clients. Designed for durability, efficiency, and thermal performance, our tanks undergo rigorous testing to ensure maximum safety and longevity.

Our production process incorporates advanced fabrication techniques and premium-grade materials to withstand harsh environmental conditions and electrical stresses. Each tank is crafted to meet industry standards and client-specific requirements, ensuring optimal performance and reliability. We emphasize precision welding, corrosion-resistant coatings, and robust structural design to deliver tanks that offer superior protection for critical transformer components.

To enhance accuracy, efficiency, and scalability, Hindusthan Fabrication Industries integrates CNC Plasma Cutting Machines into its core fabrication processes. These computer-controlled systems deliver highly accurate and consistent cuts across a wide variety of metals, including mild steel, stainless steel, and aluminum—regardless of complexity or thickness.

CNC plasma cutting enables us to execute intricate designs with sharp precision, reducing human error and ensuring repeatable quality in high-volume production. This technology significantly reduces production time, minimizes material waste, and supports cost-effective fabrication for both standard and custom components.

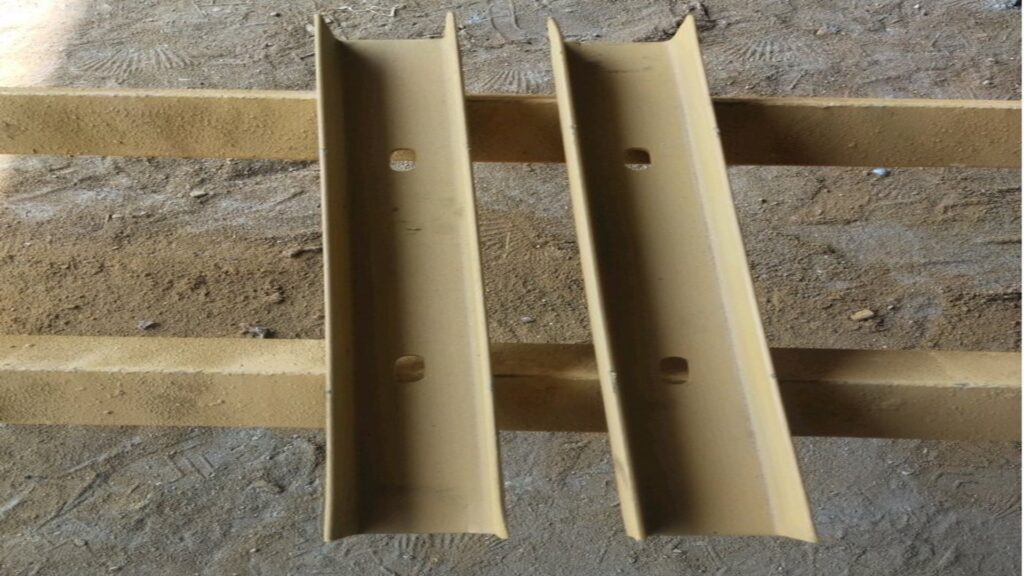

As part of our advanced transformer tank manufacturing division, Hindusthan Fabrication Industries specializes in the production of High-Precision Core Channels—essential components that ensure the mechanical alignment, magnetic balance, and overall structural integrity of transformer cores.

These channels are meticulously engineered using High-Grade, Low-Loss Electrical Steel and fabricated with cutting-edge equipment to achieve consistent dimensional accuracy and structural strength. By maintaining exact spacing and alignment of core laminations, our core channels play a vital role in reducing noise, minimizing vibrations, and enhancing thermal performance.